COURSE OBJECTIVES

Ø To understand and develop knowledge on the various flexible manufacturing systems and its applications.

Ø To get introduced to the simulation process and FMS database.

Ø To explore the future prospects of AI and Expert systems in FMS.

UNIT 1 INTRODUCTION

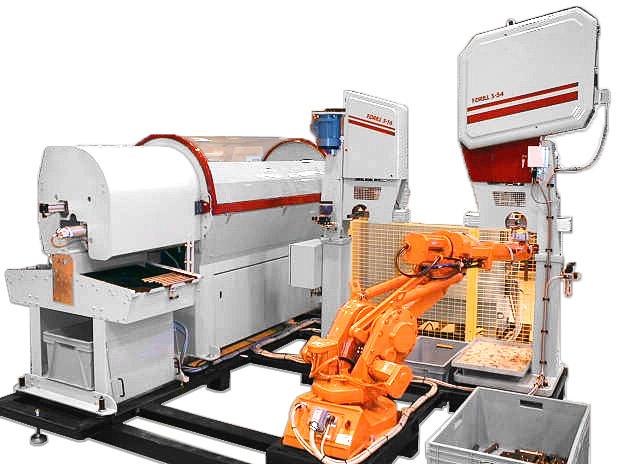

FMS– development of manufacturing systems – benefits – major elements – types of flexibility-part selection problems– FMS application and flexibility –single product, single batch, N – batch scheduling problem – knowledge based scheduling system.

UNIT 2 COMPUTER CONTROL AND SOFTWARE FOR FLEXIBLE MANUFACTURING SYSTEMS

Introduction – composition of FMS– hierarchy of computer control –computer control of work center and assembly lines – FMS supervisory computer control – types of software specification and selection – Object oriented control architecturetrends.

UNIT 3 FMS SIMULATION AND DATA BASE

Application of simulation–model of FMS–simulation software – limitation – manufacturing data systems–data flow–FMS database systems–planning for FMS database- predictive control algorithms for on line scheduling of FMS.

UNIT 4 GROUP TECHNOLOGY AND JUSTIFICATION OF FMS

Introduction – matrix formulation – mathematical programming formulation –graph formulation – knowledge based system for group technology – economic justification of FMS- application of possibility distributions in FMS systems justification- Measuring flexibility and performance of FMS.

UNIT 5 APPLICATIONS OF FMS AND FACTORY OF THE FUTURE

FMS application in machining, sheet metal fabrication, prismatic component production – aerospace application – Case

studies. FMS development towards factories of the future – artificial intelligence and expert systems in FMS – design philosophy and characteristics for future.

COURSE OUTCOMES

On completion of the course, student will be able to

CO1 - Identify the need and role of Flexible Manufacturing System in Industry.

CO2 - Assess the concepts and linkage of software in FMS.

CO3 - Demonstrate the simulation process involved and its data flow.

CO4 - Justify the importance of FMS and its importance in group technology.

CO5 - Compare and categorise the level of FMS needed in an manufacturing industry.

CO6 - Appreciate and explore the penetration of AI in FMS.

TEXT / REFERENCE BOOKS

1 Jha, N.K. “Handbook of flexible manufacturing systems”, Academic Press Inc., 2012.

2 Radhakrishnan P. and Subramanyan S., “CAD/CAM/CIM”, Wiley Eastern Ltd., New Age International Ltd., 2010.

3 Raouf, A. and Ben-Daya, M., Editors, “Flexible manufacturing systems: recent development”, Elsevier Science, 2015.

4 Jan Beier, “Simulation approach towards energy flexible manufacturing systems”, Springer Publications, 2017.

5 H.K. Shivanand, “Flexible Manufacturing System”, New Age International Publishers, 2011.

6 Taiichi Ohno, “Toyota production system: beyond large-scale production”, Productivity Press (India) Pvt. Ltd. 2013.

END SEMESTER EXAMINATION QUESTION PAPER PATTERN

Max. Marks : 100 Exam Duration: 3 Hrs.

PART A: 10 Questions of 2 marks each-No choice 20 Marks

PART B: 2 Questions from each unit with internal choice, each carrying 16 marks 80 Marks

- ஆசிரியர்: RAM PRAKASH S