Search results: 406

Mechanical engineering plays a dominant role in enhancing safety, economic vitality, enjoyment and overall quality of life throughout the world. Mechanical engineers are concerned with the principles of force, energy and motion. Mechanical engineering is a diverse subject that derives its breadth from the need to design and manufacture everything from small individual parts and devices (e.g. microscale sensors and inkjet printer nozzles) to large systems (e.g. spacecraft and machine tools).

The role of a mechanical engineer is to take a product from an idea to the marketplace. In order to accomplish this, a broad range of skills are needed. Since these skills are required for virtually everything that is made, mechanical engineering is perhaps the broadest and most diverse of engineering disciplines.

- Teacher: ARUNKUMAR G

Thermodynamics is a very important branch of science and engineering that studies the role of heat and its relation to energy and work. This course introduces you to the core concepts of thermodynamics such as the relationship between pressure, volume, and temperature and how changes in one can affect the others. You will also look at examples and solve certain problems in order to help you better understand the concept of thermodynamics.

- Teacher: JAYAPRABAKAR J

- Teacher: Dr. Karthikeyan A

- Teacher: SENTHILKUMAR G

SMEA1303 FLUID MECHANICS AND FLUID MACHINERY

COURSE OBJECTIVES

To understand the fluid properties, flow characteristics and hydrostatic force on surfaces.

To study the equation of motions such as mass, momentum and energy equation and their practical applications.

To understand the functioning and characteristic curves of hydraulic machines.

UNIT 1 FLUID PROPERTIES 9 Hrs.

Fluid Properties: Density-Specific Weight-Specific Gravity-viscosity-surface tension-capillarity-Vapour pressure-compressibility. Fluid Static: Hydrostatic Law-Pressure Variation in static fluid-Hydrostatic force on a submerged plane surfaces-Location of hydrostatic force. Manometers-Simple, U tube and differential Manometers. Buoyancy-Meta centric height-determination of stability of floating bodies and submerged bodies.

UNIT 2 EQUATIONS OF MOTION 9 Hrs.

Types of fluid flow-Concept of Control Volume- Control Volume Analysis of mass, momentum and energy. Differential equation of continuity and momentum - Euler’s and Bernoulli’s Equation and its applications. Flow Measurement: Orifice meter, Venturi meter, Piezometer, Pitot tube.

UNIT 3 FLOW THROUGH ORIFICE, NOTCHES, WEIRS AND PIPES 9 Hrs.

Hydraulic co-efficient-Flow through orifice, Notches and weirs. Laminar and Turbulent flow-Reynolds experiment-laminar flow through circular pipe (Hagen poiseulle’s)-Major and minor losses in pipes-Darcy weisbach’s equation, chezy’s formula-friction factor- moody diagram-pipes in series and pipes in parallel-total energy line-hydraulic gradient line-Equivalent pipe. Concept of Boundary Layer-Types of boundary layer thickness-drag on flat plate.

UNIT 4 PUMPS 9 Hrs.

Centrifugal Pumps: Introduction-Definitions of heads and efficiencies-Operations-work done by the Impeller with Velocity triangles-Performance curves-Cavitations-Multi-staging: Pumps in Series and Parallel. Reciprocating Pumps: Operation–power required driving the pump-Slip-indicator Diagram–Separation-Air vessels.

UNIT 5 TURBINES AND DIMENSIONAL ANALYSIS 9 Hrs.

Hydraulic Turbines: Classification of hydraulic turbines-Working principle of Pelton wheel, Francis and Kaplan turbines-velocity triangles-draft tube-hydraulic turbine characteristics. Governing of turbines. Dimensional Analysis: Needs and methods-Buckingham’s π Theorem, Non-Dimensional Numbers, Similarities of flow. Model studies. Max. 45 Hrs.

COURSE OUTCOMES

On completion of the course, student will be able to

CO1 - Understand the different properties of fluids and compute the fluid pressure in a pipe & hydrostatic forces acting on different surfaces.

CO2 - Analyze the Bernoulli’s theorem and applies it in engineering application.

CO3 - Evaluate and compare (i) the hydraulic coefficients and (ii) the energy losses in pipes.

CO4 - Explain the principle, working and operating characteristic curves of different types of pumps and estimate the power required.

CO5 - Distinguish the principle, working and operating characteristic curves of different types of turbines and compute the power developed.

CO6 - Understand the methods of dimensional analysis and application in model analysis.

TEXT / REFERENCE BOOKS

1. Bansal R.K., "Fluid Mechanics & Hydraulics Machines", 9th Edition, Laxmi Publications, 2015.

2. Modi P.N., Seth S.M., "Hydraulics and Fluid Mechanics Including Hydraulic Machines", 21st Edition, Standard Book House, 2017.

3. Goyal, Manish Kumar, "Fluid Mechanics and Hydraulic Machines", PHI Learning Pvt. Ltd., 2015.

4. Kumar K.L., "Engineering Fluid Mechanics", 8th Edition, Eurasia Publication House (P) Ltd, 2014.

5. Rajput R.K., "Fluid Mechanics & Hydraulics Machines", 4th Edition, S. Chand Limited, 2008.

6. Yunus.A.Cengel, John.M.Cimbala, "Fluid Mechanics Fundamentals and Application", 3rd Edition, Tata McGraw Hill, 2013.

7. Robert W. Fox, Alan T. McDonald, Philip J. Pritchard, John W. Mitchell, "Fluid Mechanics", 9th Edition, Wiley India, 2016.

8. Franck M. White, "Fluid Mechanics", 8th Edition, Tata McGraw Hill Publication, 2015.

- Teacher: Madhan Kumar G

COURSE OBJECTIVES

To study the aspects of Strength, Stiffness and Stability.

To gain knowledge of different types of stresses, strain and deformation induced in the components due to external loads.

To study the distribution of various stresses in the elements such as beams, shafts etc.

To study the effect of component dimensions and shapes on the stresses and deformations.

UNIT 1 STRESS STRAIN DEFORMATION OF SOLIDS 9 Hrs.

Rigid and Deformable bodies – Strength, Stiffness and Stability – Stresses; Tensile, Compressive and Shear – Deformation of simple and compound bars under axial load – Thermal stresses and strains. Elastic constants – Relation between Elastic constans- Strain energy and unit strain energy – Strain energy in uniaxial loads.

UNIT 2 ANALYSIS OF STRESSES IN TWO DIMENSIONS 9 Hrs.

Principal planes and stresses – Mohr’s circle for biaxial stresses – Maximum shear stress - simple problems- Stresses on inclined planeBiaxial state of stresses – Thin cylindrical and spherical shells – Deformation in thin cylindrical and spherical shells – Efficiency of joint- Effect of Internal Pressure.

UNIT 3 BEAMS - LOADS AND STRESSES 9 Hrs.

Types of beams - Supports and Loads – Shear force and Bending Moment in beams – Cantilever, Simply supported and Overhanging beams – SFD and BMD for inclined loads and couples.Stresses in beams – Theory of simple bending – Stress variation along the length and in the beam section – Effect of shape of beam section on stress induced.

UNIT 4 TORSION 9 Hrs.

Analysis of torsion of circular bars – Shear stress distribution – Bars of Solid and hollow circular section – Stepped shaft – Twist and torsion stiffness – Composite shafts Springs - Laminated springs, axial load and twisting moment acting simultaneously both for open and closed coiled springs– Deflection of helical coil springs under axial loads – stresses in helical coil springs under torsion.

UNIT 5 BEAM DEFLECTION 9 Hrs.

Columns – End conditions – Equivalent length of a column – Euler equation – Slenderness ratio – Rankine Gordon formula for columns. Elastic curve of Neutral axis of the beam under normal loads – Evaluation of beam deflection and slope: Double integration method, Macaulay Method, and Moment-area Method.

COURSE OUTCOMES

On completion of the course, student will be able to

CO1 - Understand the fundamentals of Stress and Elastic Constants.

CO2 - Understand the concept of Principal stresses and thin shells.

CO3 - Create Shear force & Bending moment diagram and Bending stress.

CO4 - Apply the Concept of Torsion for Circular Shafts and Understand the concept of Springs.

CO5 - Understand the theory of Column and Beam deflection.

CO6 - Analyze overall deflection aspects related to Strength, Stiffness and Stability.

TEXT / REFERENCE BOOKS

1. Bansal R.K., "Strength of Materials", Laxmi Publications Pvt. Ltd., 5th Edition, 2012.

2. Punmia B.C. & Jain A.K., Mechanics of Materials, Laxmi Publications, 2001.

3. Ryder G.H., "Strength of Materials", Macmillan India Ltd., 3rd Edition, 2002.

4. Ray Hulse, Keith Sherwin & Jack Cain, "Solid Mechanics", Palgrave ANE Books, 2004. 5. Allan F. Bower, "Applied Mechanics of Solids", CRC Press, 2009.

- Teacher: Madhan Kumar G

COURSE OBJECTIVES

To provide essential knowledge of construction and working of various types of power plants.

To detail the role of Mechanical Engineers in their operation and maintenance

- Teacher: R Siva

Provide the insights of the fundamentals of Mechanisms and Cams.

Understand the basics of Flywheels, Balancing of Rotating and Reciprocating unbalance systems.

Enhance knowledge of Single degree - Free and Damped Vibrations.

Provide the detailed overview of Forced Vibrations.

Discuss the fundamentals of Gyroscopes and Governors.

- Teacher: RAM PRAKASH S

On completion of the course, student will be able to

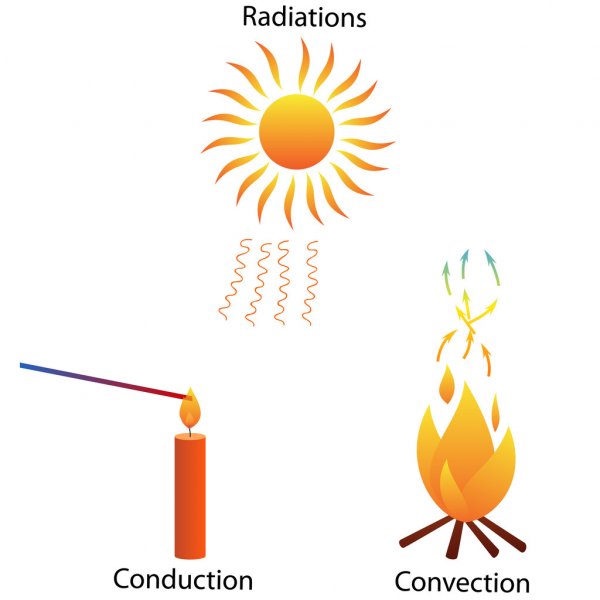

CO1 - Understand the basic modes of heat transfer and Compute temperature distribution in steady-state and

unsteady-state heat conduction.

CO2 - Understand and analyze heat transfer through extended surfaces.

CO3 - Interpret and analyze forced and free convection heat transfer.

CO4 - Explore the real time applications of radiation mode of heat transfer.

CO5 - Design heat exchangers using LMTD and NTU methods.

CO6 - Relate the mass transfer concepts for various industrial applications.

- Teacher: Dr. Karthikeyan A

To understand the concept and basic mechanics of metal cutting, working of standard machine tools such as

lathe, shaping and allied machines, milling, drilling and allied machines, grinding and allied machines and

broaching.

To understand the basic concepts of Computer Numerical Control (CNC) of machine tools and CNC

Programming.

- Teacher: ARUNKUMAR G

- Teacher: Sangeetha M

COURSE OBJECTIVES

To discuss the concepts of compressible and Incompressible fluids.

To understand Mach number variation on area ratio.

To impart in depth knowledge on the flow characteristics through constant area duct.

UNIT 1 FUNDAMENTALS OF COMPRESSIBLE FLUID FLOW 9 Hrs.

Concept of compressible flow, Energy and momentum equations, various regions of flow, fluid velocity, stagnation state, velocity of sound, critical states, Mach number, critical mach number, Crocco number, types of waves, mach cone, mach angle, effect of mach number on compressibility.

UNIT 2 FLOW THROUGH VARIABLE AREA DUCTS 9 Hrs.

Isentropic flow through variable area duct, T-S and h-s diagrams for nozzle and diffuser flows, area ratio as a function of Mach number, Mass flow rate through nozzles and diffusers, effect of friction in flow through nozzles.

UNIT 3 FANNO FLOW AND RAYLEIGH FLOW 9 Hrs.

Flow in constant area duct with friction - Fanno curves, and Fanno Flow equations, variation of flow properties, variation of Mach number with duct length. Flow in constant area duct with heat transfer, Rayleigh line and Rayleigh flow equations, variation of flow properties, maximum heat transfer.

UNIT 4 NORMAL SHOCK AND OBLIQUE SHOCKS 9 Hrs.

Governing equations, variation of flow parameters, static pressure, static temperature, density, stagnation pressure, entropy across normal shock and oblique shocks. Normal shocks - stationary and moving, applications. Prandtl Meyer equation, impossibility of shock in sub-sonic flows, flow in convergent and divergent nozzles with shock, Flows with oblique shock.

UNIT 5 JET AND SPACE PROPULSION 9 Hrs.

Aircraft propulsion, types and working of jet engines - energy transfer in jet engines, thrust, thrust power, propulsive and overall efficiencies, thrust augmentations in turbo jet engines, ram jet and pulse jet engines. Rocket propulsion, types of rocket engines, Liquid and solid fuel rocket engines, Introduction to Electrical and Nuclear rockets-Space Flights, Orbital and escape velocity.

COURSE OUTCOMES

On completion of the course, students will be able to

CO1 - Recall the fundamental concepts of compressible fluid flow.

CO2 - Demonstrate the significance of mach number on compressibility.

CO3 - Differentiate isothermal flow and isentropic flow.

CO4 - Apply the concept of normal shocks to different turbo machines.

CO5 - Estimate the heat transfer in flow through constant area ducts.

CO6 - Calculate the propulsive power in jet engines.

- Teacher: SENTHILKUMAR G

- Teacher: VENKATESAN S P

To draw complex geometries of machine components in sketcher mode.

To create complex engineering assemblies using appropriate assembly constraints.

To write programs to generate analytical and synthetic curves used in engineering practice.

To generate freeform shapes in part mode to visualize components.

To develop ‘G’ and ‘M’ codes for turning and milling components and to generate automated tool paths for a

given engineering component.

To generate automated tool paths for a given engineering component.

- Teacher: Sangeetha M

COURSE OBJECTIVES

To understand the underlying principles of operation of different IC engines and components.To provide knowledge on emission formation, control, alternate fuel etc.

- Teacher: Senthilkumar J

COURSE OBJECTIVES

To understand the underlying principles of operation of different IC engines and components.To provide knowledge on emission formation, control, alternate fuel etc.

- Teacher: HEMANANDH J

- Teacher: JAYAPRABAKAR J