- Teacher: Durairaj .

- Teacher: K BALACHANDAR

To provide the fundamentals, components and industrial applications of automation.

To provide the automation facilities offered by automation in machine tools, manufacturing and materials handling.

To provide basic knowledge of the modern automation systems.

- Teacher: Sangeetha M

COURSE OBJECTIVES

1. To learn fundamental concepts of Stress, Strain and deformation of solids with applications.

2. To know the method of finding slope and deflection of beams. ÿ To understand the effect of torsion on shafts.

3. To understand the basic properties of the fluid, fluid kinematics, fluid dynamics and to analyse and appreciate the complexities involved in solving the fluid flow problems.

4. To develop understanding about hydrostatic law, principle of buoyancy and stability of a floating body and application of mass, momentum and energy equation in fluid flow.

5. To understand bioelectric amplifiers.

UNIT 1 STRESS STRAIN AND DEFORMATION OF SOLIDS, STATES OF STRESS 9 Hrs.

Rigid bodies and deformable solids - stability, strength, stiffness - tension, compression and shear stresses - strain, elasticity, Hooke’s law, limit of proportionately, modules of elasticity, stress-strain curve, lateral strain - temperature stresses deformation of simple and compound bars - shear modulus, bulk modulus, relationship between elastic constants - bi axial state of stress - stress at a point - stress on inclined plane - principal stresses and principal planes - Mohr’s circle of stresses.

UNIT 2 BENDING MOMENT IN BEAMS AND TORSION OF SHAFTS 9 Hrs.

Introduction, Types of beams, loads and reactions, Shear force and bending moment in beams – Cantilevers – Simply supported beams. Numerical on Shear force and bending moment diagrams for Cantilevers – Simply supported beams subjected to various loading condition-SFD and BMD for uniformly Distributed load (UDL) and Point load. TorsionIntroduction, assumptions, derivation of torsional equations, torsional rigidity/stiffness of shafts. Power transmitted by solid and hollow circular shafts.

UNIT 3 FLUID PROPERTIES 9 Hrs.

Fluid Properties: Density - Specific Weight - Specific Gravity - Viscosity - Surface tension - Capillarity - compressibility. Fluid Statics: Hydrostatic Law - Pressure Variation in static fluid - Hydrostatic force on a submerged plane surface - Location of hydrostatic force. Manometers - Simple U tube and differential manometers - Buoyancy - Meta-centric height - determination of stability of floating bodies and submerged bodies.

UNIT 4 EQUATIONS OF MOTION 9 Hrs.

Basic equations of motion: Types of fluid flow-Concept of Control Volume- Control Volume Analysis of mass, momentum and energy. Differential equation of continuity and momentum - Euler’s and Bernoulli’s Equation and its applications. Flow Measurement: Orifice meter, Venturi meter, Piezometer.

UNIT 5 FLUID DYNAMICS AND FLOW THROUGH PIPES 9 Hrs.

Flow through orifices: Classification - Hydraulic co-efficient - Flow through rectangular orifice, Notches and weirs. Laminar and Turbulent flow: Reynolds experiment - Major and minor losses in pipes - Darcy Weisbach’s equation, Chezy’s formula - pipes in series and pipes in parallel - total energy line - hydraulic gradient line - Equivalent pipe.

Max. 45 Hrs.

COURSE OUTCOMES

On completion of the course, student will be able to

CO1 - Analyze the state of stress and strain at any point in a member.

CO2 - Identify, formulate, and solve structural engineering problems.

CO3 - Calibrate flow discharge measuring device used in pipes channels and tanks.

CO4 - Apply Hagen Poisueille’s equation to solve numerical Problems.

CO5 - Characterize laminar and turbulent flows.

CO6 - Interpret different pipe fittings and evaluate the fluid velocity considering major and minor losses.

TEXT / REFERENCE BOOKS

1. Rajput.R.K. “Strength of Materials” 4th Edition, S.Chand & Co., New Delhi, 2002.

2. Khurmi, R.S, “Strength of Materials“, 23rd Edition, S.Chand & Co., 2008.

3. Bansal.R.K., “Fluid Mechanics & Hydraulics Machines”, 9th Edition, Laxmi Publications, 2005.

4. Kumar K. L., “Engineering Fluid Mechanics”, 8th Edition, Eurasia Publication, 2009.

- Teacher: Dr. ANISH M

COURSE OBJECTIVES:

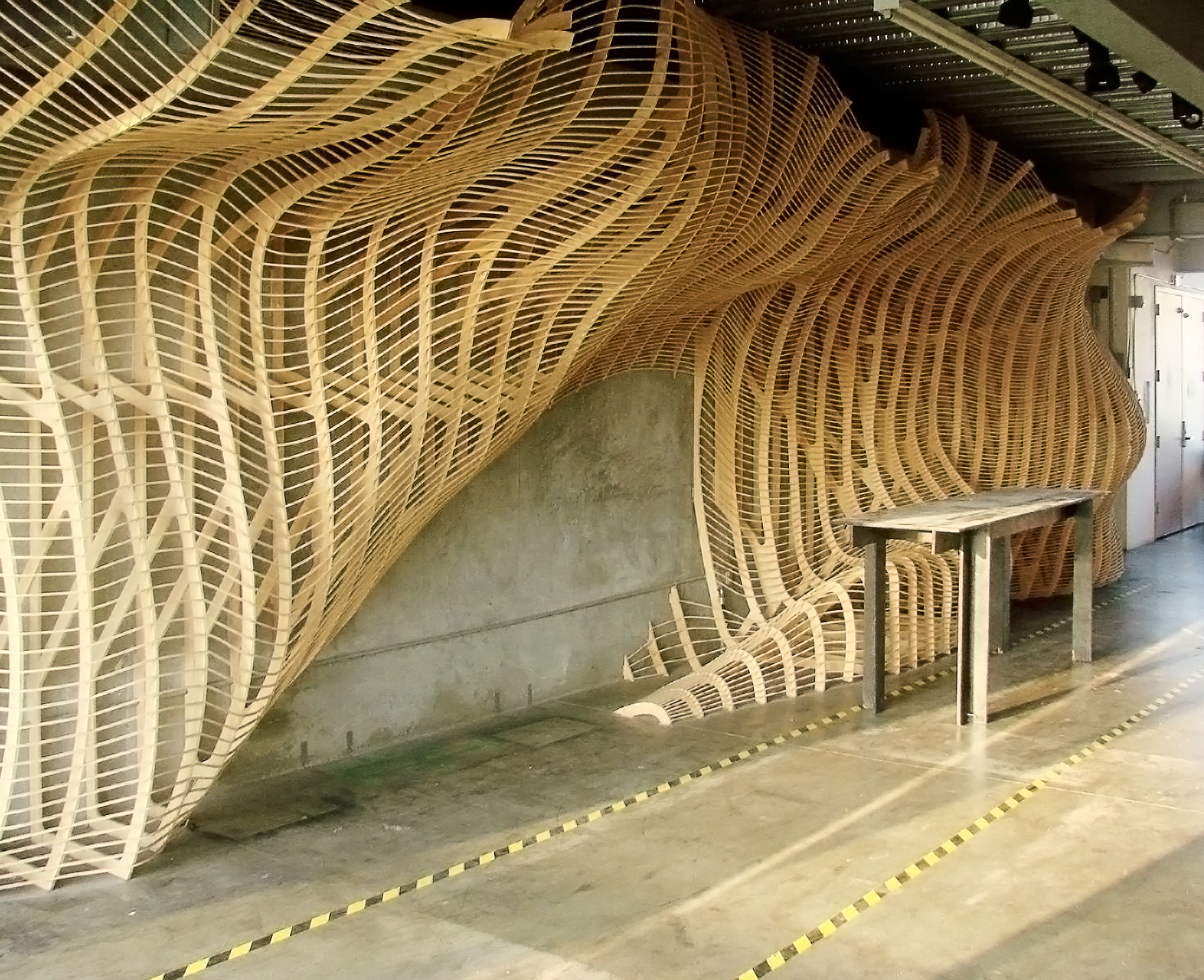

- To reinforce the concepts of 3D modelling.

- To enable them to experiment with forms, mapping, rendering and presentation techniques.

- To prepare the student for mass production of furniture for various classes of people with the parameters of economy and culture

SYLLABUS:

UNIT 1 MATERIAL AND PROCESSES IN DESIGN

Material Deposition Processes Laser Deposition, Micro-Plasma Powder Deposition, Chemical vapour Deposition, Micro Welding, Powder Casting Metal 3D Printing, Powder Deposition 3D printing;

UNIT 2 SUBTRACTIVE MANUFACTURING

Subtractive Processes Electrochemical machining, Electro-Discharge machining, Ultrasonic Machining, Laser Beam Machining, Water jet machining, Abrasive Jet Machining, Plasma Arc machining; Cutting and Removal Water Jet Cutting, Plasma Cutting, Laser Cutting, Electro-Discharge Wire Cutting; Abrasive Jet Cutting

UNIT 3 ADDITIVE MANUFACTURING

Additive Extrusion Processes Extruded Filament 3D printing, Clay 3D printing, Stereo lithography; Special Purpose Manufacturing processes- Rot molding, Layer Compression, Sheet contouring, Friction Welding

UNIT 4 SURFACE TREATMENT PROCESSES

Surface Treatment Processes Laser Etching, Acid/Base Etching, Electro Chemical Etching, Sand Blast Etching, Ultraviolet Etching, Photochemical Machining Electro Chemical Polishing

UNIT 5 CONSTRUCTIVE ASSIGNMENTS

Demonstrate comprehensive understanding through accompanying assignments, group discussions, and site visits.

COURSE OUTCOME:

- Understand the various subtractive manufacturing processes frequently used in Interior and furniture design.

- Compare the various new technologies being incorporated into manufacturing processes

- Comprehend the various subtractive manufacturing processes frequently used in Interior and furniture design.

- Discuss the various additive manufacturing processes frequently used in Interior and furniture design.

- Analyse the various surface treatment processes in the manufacturing of interior design elements.

- Develop systematic design approach and space planning through manufactured furniture as elements of design.

- Teacher: Yusuf Chiniwala