Search results: 1467

The course is consists of all non-conventional manufacturing processes. It starts with classification of manufacturing processes and necessity of non conventional manufacturing processes. This course dealt with details about the mechanism of material removal, sources of energy used for material removal, working principle, the set up or equipment and relative advantages and disadvantages. It gives a clear cut idea about the processes, its use in specific industrial application etc.

- Teacher: ARUNKUMAR G

- Teacher: Kanimozhi B

COURSE OBJECTIVES

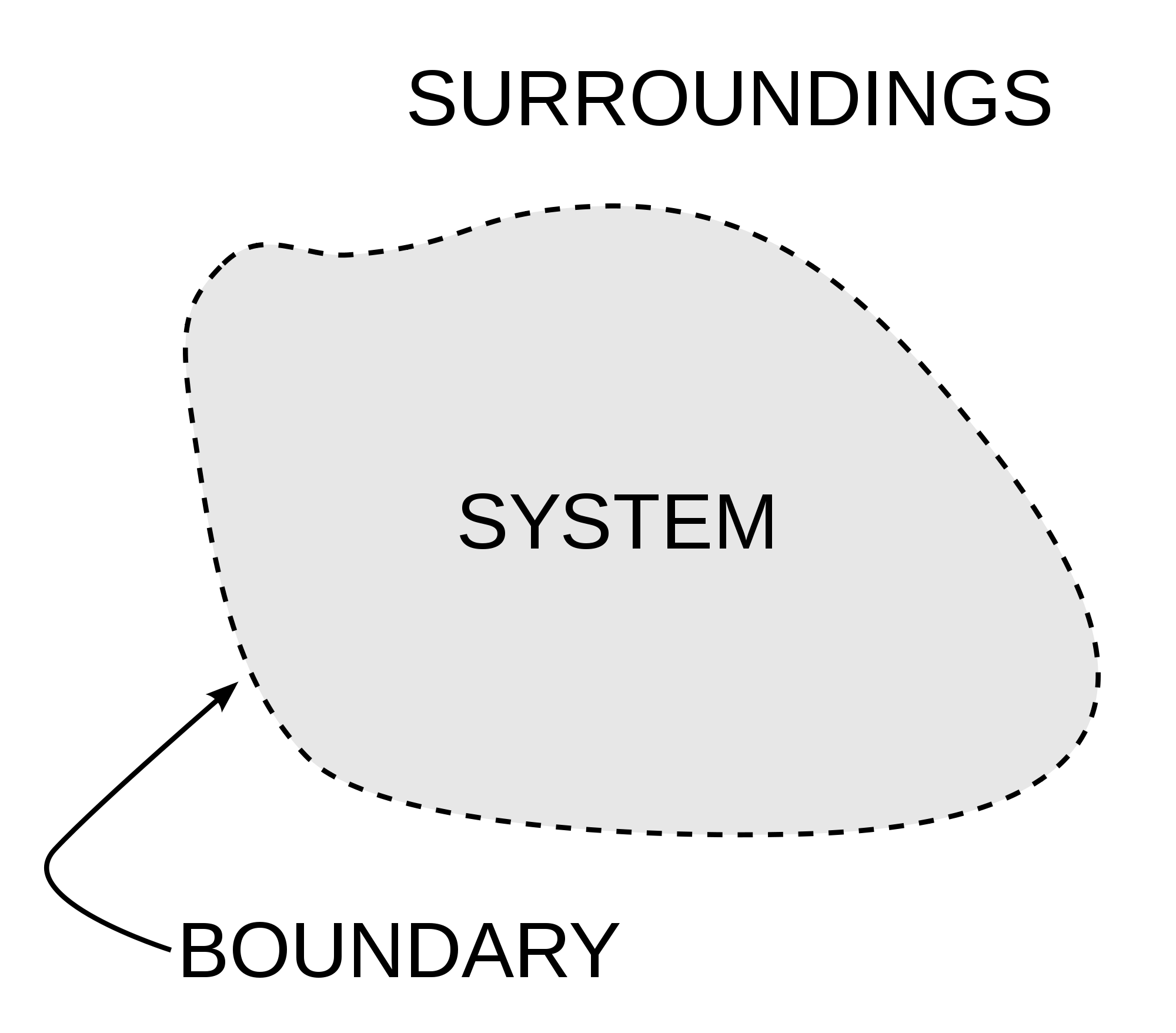

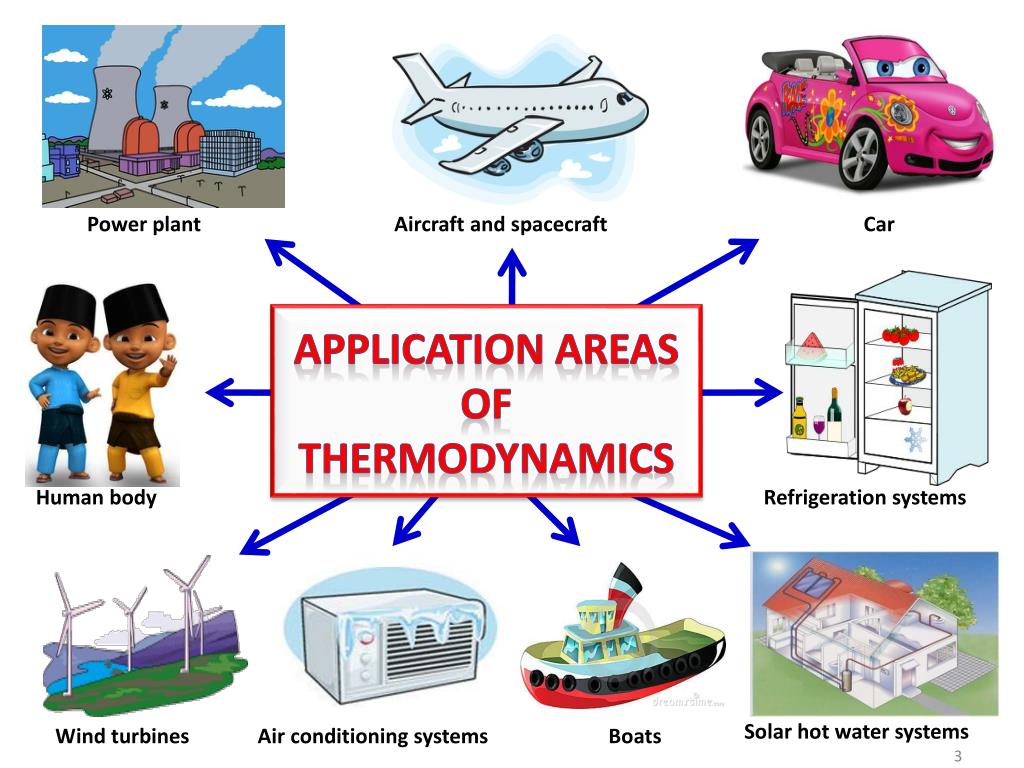

To understand the basic concepts of thermodynamics.

To comprehend laws of thermodynamics and apply it to the related processes.

Perform thermal analysis on behavior and performance of systemsTime Table

Monday-12.00 to 1.00 pm

Wednesday-9.30 to 10.30

Friday-11.00 to 12.00 pm

Saturday 8.30 to 9.30

- Teacher: SENTHILKUMAR G

- Teacher: VENKATESAN S P

COURSE OBJECTIVE

To introduce the fundamentals of electric and hybrid vehicle technology

To understand the design and operation of electric and hybrid vehicle powertrains

To evaluate the performance and efficiency of electric and hybrid vehicles

To analyze the environmental impact of electric and hybrid vehicles

COURSE OUTCOMES

On completion of the course, students will be able to CO1 - Explain the basic principles and technologies used in electric and hybrid vehicles. CO2 - Analyze the design and operation of electric and hybrid vehicle powertrains. CO3 - Evaluate the performance and efficiency of electric and hybrid vehicles. CO4 - Analyze the environmental impact of electric and hybrid vehicles. CO5 - Interpret the role of battery technology in electric and hybrid vehicles.

TEXT / REFERENCE BOOKS

1. Huang, Y., & Ji, C. (2021). Advanced control of electric vehicles. Elsevier.

2. Zhu, X., Chen, Y., & Mi, C. (2021). Power electronics for electric vehicles: technology and design.

Springer.

3. Zhang, J., Liu, C., & Tang, T. (2018). Powertrain and Energy System Optimization for Hybrid

Vehicles. Springer.

4. Adachi, T., Kikuchi, K., & Kawamura, T. (2018). Electric Vehicles - Modelling and Simulations.

InTechOpen.

5. Li, J., Lu, X., & Yu, W. (2020). Battery Management System for Electric Vehicles: Theory and

Applications. Springer.

- Teacher: Bupesh Raja V.K

COURSE OBJECTIVES

To Understand the fundamentals of wind energy and its conversion system

To learn about solar radiation and solar collectors

- Teacher: Dr. Karthikeyan A

COURSE OBJECTIVES

To provide strong understanding of geometric modelling techniques used for creating the CAD models.

To make the awareness about the computer applications to the manufacturing and factory operations.

To offer the fundamental knowledge of the numerical methods to perform the design analysis.

COURSE OUTCOMES

On completion of the course, student will be able to:

CO1 - Interpret how the geometric modelling techniques are applied to make the product designs.

CO2 - Create the CAD models using sketch tools, design features, assembly, and drawing annotations in a CAD package.

CO3 - Explain how the computer packages are employed in the direct and/or indirect manufacturing applications.

CO4 - Make a mechanical component using CNC machine/ 3D printer.

CO5 - Determine the nodal solutions to the one-dimensional element finite element problems.

CO6 - Perform the structural analyses of the stated 1D, 2D and 3D structural problems from solid mechanics.

COURSE CONTENT

UNIT 1 CAD FUNDAMENTALS 6 Hrs.Computer graphics fundamentals, geometric transformation, viewing transformation, line generating algorithms, and hidden line removal algorithms.

UNIT 2 GEOMETRIC MODELING 6 Hrs.

Wireframe modelling: analytical curves and synthetic curves. Surface modelling: analytical surfaces and synthetic surfaces. Solid modelling: constructive solid geometry (CSG), boundary representation, parametric modelling. Assembly modelling.

UNIT 3 CAM APPLICATIONS IN FACTORY OPERATIONS 6 Hrs.

Indirect computer applications: Computer Aided Process Planning (CAPP), Computer aided quality testing, Computer aided process monitoring, Computer integrated production system (CIPS), Enterprise resource planning (ERP).

UNIT 4 CNC PROGRAMMING 6 Hrs.

NC, DNC and CNC machine tools, rapid prototyping. NC Programming: point to point and continuous path machining approaches, G Codes, M Codes, Canned cycles, Manual NC programming for turning and milling operations.

UNIT 5 COMPUTER AIDED ANALYSIS FUNDAMENTALS 6 Hrs.

General form of finite element equation, Numerical solutions to one-dimensional problems from solid mechanics. Steps in finite element analysis.

LIST OF EXPERIMENTS 30 Hrs.

Activity 1: 2D Sketching using a CAD package.

Activity 2: 3D Part modelling using a CAD package.

Activity 3: 3D Assembly modelling using a CAD package.

Activity 4: Drawing a sheet with different model views, annotations and dimensions using a CAD package.

Activity 5: Apply rendering effects to the models using a CAD package.

Activity 6: NC Turning using an NC simulation software.

Activity 7: NC Machining using an NC simulation software.

Activity 8: Make a component using a CNC turning centre.

Activity 9: Make a component using a CNC machining centre.

Activity 10: Make a prototype using a 3D printing.

Activity 11: Structural analysis of one-dimensional element (bar) problems using an FEA package.

Activity 12: Structural analysis of one-dimensional element (beam) problems using an FEA package.

Activity 13: Structural analysis of one-dimensional element (truss) problems using an FEA package.

Activity 14: Structural analysis of two-dimensional element (plate) problems using an FEA package.

Activity 15: Structural analysis of three-dimensional element (solid component) problems using an FEA package.

TEXT / REFERENCE BOOKS

1. Zhuming Bi and Xiaoqin Wang, "Computer Aided Design and Manufacturing", Wiley, 2020.2. Ibrahim Zeid and R. Sivasubramanian, "CAD/CAM: Theory and Practice: Special Indian Edition", 2nd Edition, McGraw Hill Education, 2009, 828 Pages.

3. Sudip S. Bhattacharjee, "Finite Element Analysis of Solids and Structures", CRC Press, 2021.

4. Kuang-Hua Chang, "E-Design: Computer-Aided Engineering Design", Elsevier Science, 2016.

5. Donald D. Hearn and M. Pauline Baker, "Computer Graphics, C Version", 2nd Edition, Pearson Education, 2014, 660 pages.

6. Pawan Negi, Mangey Ram, Om Prakash Yadav, "Basics of CNC Programming", River Publishers, 2022.

- Teacher: JEYA JEEVAHAN J

- Teacher: Dr.R Narmadha

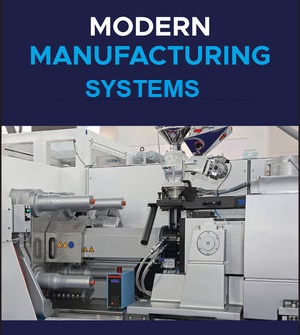

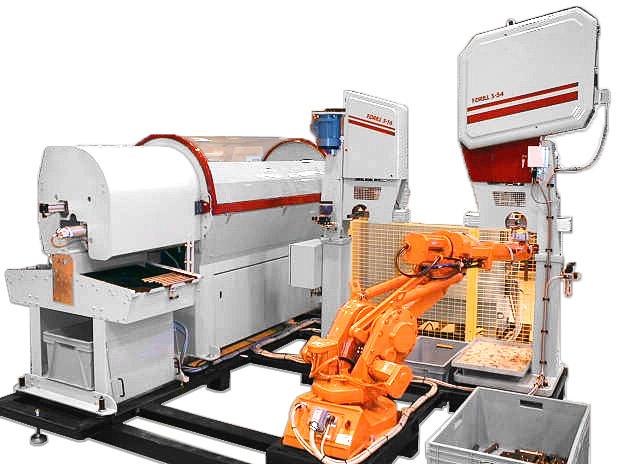

A flexible manufacturing system (FMS) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted.

This flexibility is generally considered to fall into two categories, which both contain numerous subcategories.The first category is called as Routing Flexibility which covers the system's ability to be changed to produce new product types, and ability to change the order of operations executed on a part.The second category is called Machine Flexibility which consists of the ability to use multiple machines to perform the same operation on a part, as well as the system's ability to absorb large-scale changes, such as in volume, capacity, or capability.

Most FMS consist of three main systems:

- The "Work Machines" which are often automated "CNC machines" are connected by

- By a "Material handling" system to optimize parts flow and

- The "Central Control Computer" which controls material movements and machine flow.

The main advantages of an FMS is its high flexibility in managing manufacturing resources like time and effort in order to manufacture a new product.

The best application of an FMS is found in the production of small sets of products like those from a mass production.

- Course Coordinator: ARUNKUMAR G

COURSE OBJECTIVES

Ø To understand and develop knowledge on the various flexible manufacturing systems and its applications.

Ø To get introduced to the simulation process and FMS database.

Ø To explore the future prospects of AI and Expert systems in FMS.

UNIT 1 INTRODUCTION

FMS– development of manufacturing systems – benefits – major elements – types of flexibility-part selection problems– FMS application and flexibility –single product, single batch, N – batch scheduling problem – knowledge based scheduling system.

UNIT 2 COMPUTER CONTROL AND SOFTWARE FOR FLEXIBLE MANUFACTURING SYSTEMS

Introduction – composition of FMS– hierarchy of computer control –computer control of work center and assembly lines – FMS supervisory computer control – types of software specification and selection – Object oriented control architecturetrends.

UNIT 3 FMS SIMULATION AND DATA BASE

Application of simulation–model of FMS–simulation software – limitation – manufacturing data systems–data flow–FMS database systems–planning for FMS database- predictive control algorithms for on line scheduling of FMS.

UNIT 4 GROUP TECHNOLOGY AND JUSTIFICATION OF FMS

Introduction – matrix formulation – mathematical programming formulation –graph formulation – knowledge based system for group technology – economic justification of FMS- application of possibility distributions in FMS systems justification- Measuring flexibility and performance of FMS.

UNIT 5 APPLICATIONS OF FMS AND FACTORY OF THE FUTURE

FMS application in machining, sheet metal fabrication, prismatic component production – aerospace application – Case

studies. FMS development towards factories of the future – artificial intelligence and expert systems in FMS – design philosophy and characteristics for future.

COURSE OUTCOMES

On completion of the course, student will be able to

CO1 - Identify the need and role of Flexible Manufacturing System in Industry.

CO2 - Assess the concepts and linkage of software in FMS.

CO3 - Demonstrate the simulation process involved and its data flow.

CO4 - Justify the importance of FMS and its importance in group technology.

CO5 - Compare and categorise the level of FMS needed in an manufacturing industry.

CO6 - Appreciate and explore the penetration of AI in FMS.

TEXT / REFERENCE BOOKS

1 Jha, N.K. “Handbook of flexible manufacturing systems”, Academic Press Inc., 2012.

2 Radhakrishnan P. and Subramanyan S., “CAD/CAM/CIM”, Wiley Eastern Ltd., New Age International Ltd., 2010.

3 Raouf, A. and Ben-Daya, M., Editors, “Flexible manufacturing systems: recent development”, Elsevier Science, 2015.

4 Jan Beier, “Simulation approach towards energy flexible manufacturing systems”, Springer Publications, 2017.

5 H.K. Shivanand, “Flexible Manufacturing System”, New Age International Publishers, 2011.

6 Taiichi Ohno, “Toyota production system: beyond large-scale production”, Productivity Press (India) Pvt. Ltd. 2013.

END SEMESTER EXAMINATION QUESTION PAPER PATTERN

Max. Marks : 100 Exam Duration: 3 Hrs.

PART A: 10 Questions of 2 marks each-No choice 20 Marks

PART B: 2 Questions from each unit with internal choice, each carrying 16 marks 80 Marks

- Teacher: RAM PRAKASH S

COURSE OUTCOME

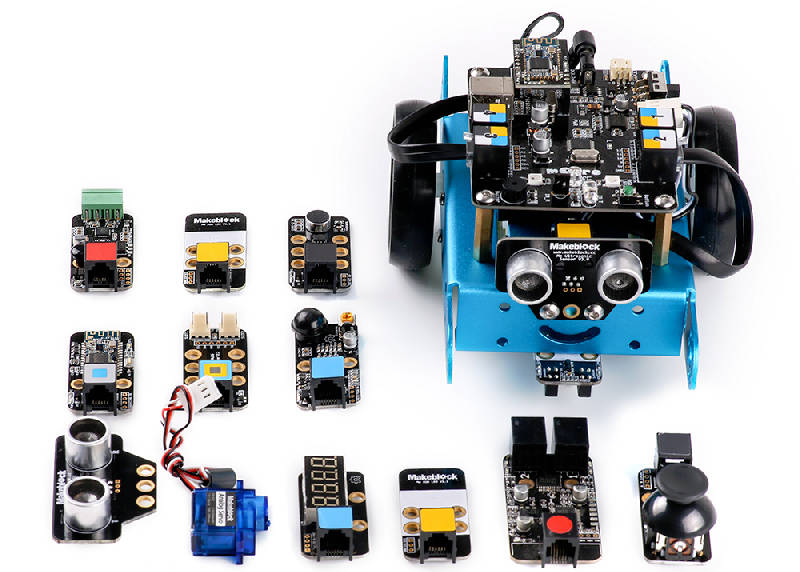

CO1: Describe the architecture of the 8085 microprocessor.

CO2: Analyse assembly language programs for 8085, incorporating various addressing modes and instruction sets.

CO3: Explain the architecture and features of the 8051 microcontroller, including memory structure, timers, interrupts, and instruction sets.

CO4: Compare and contrast ARM Cortex and OMAP processors with traditional microprocessors and microcontrollers in terms of architecture and application suitability

CO5: Design and simulate applications using 8085/8051/ARM processors for controlling hardware CO6. Develop Embedded C programs to interface peripherals and implement real-time control logic communication protocols.

- Teacher: Aranganathan A

- Teacher: Dr. G D Anbarasi Jebaselvi

- Teacher: EBENEZAR JEBARANI M R

- Teacher: Dr.R Narmadha

- Teacher: Vijaya Baskar V

COURSE OBJECTIVES

1. To learn fundamental concepts of Stress, Strain and deformation of solids with applications.

2. To know the method of finding slope and deflection of beams. ÿ To understand the effect of torsion on shafts.

3. To understand the basic properties of the fluid, fluid kinematics, fluid dynamics and to analyse and appreciate the complexities involved in solving the fluid flow problems.

4. To develop understanding about hydrostatic law, principle of buoyancy and stability of a floating body and application of mass, momentum and energy equation in fluid flow.

5. To understand bioelectric amplifiers.

UNIT 1 STRESS STRAIN AND DEFORMATION OF SOLIDS, STATES OF STRESS 9 Hrs.

Rigid bodies and deformable solids - stability, strength, stiffness - tension, compression and shear stresses - strain, elasticity, Hooke’s law, limit of proportionately, modules of elasticity, stress-strain curve, lateral strain - temperature stresses deformation of simple and compound bars - shear modulus, bulk modulus, relationship between elastic constants - bi axial state of stress - stress at a point - stress on inclined plane - principal stresses and principal planes - Mohr’s circle of stresses.

UNIT 2 BENDING MOMENT IN BEAMS AND TORSION OF SHAFTS 9 Hrs.

Introduction, Types of beams, loads and reactions, Shear force and bending moment in beams – Cantilevers – Simply supported beams. Numerical on Shear force and bending moment diagrams for Cantilevers – Simply supported beams subjected to various loading condition-SFD and BMD for uniformly Distributed load (UDL) and Point load. TorsionIntroduction, assumptions, derivation of torsional equations, torsional rigidity/stiffness of shafts. Power transmitted by solid and hollow circular shafts.

UNIT 3 FLUID PROPERTIES 9 Hrs.

Fluid Properties: Density - Specific Weight - Specific Gravity - Viscosity - Surface tension - Capillarity - compressibility. Fluid Statics: Hydrostatic Law - Pressure Variation in static fluid - Hydrostatic force on a submerged plane surface - Location of hydrostatic force. Manometers - Simple U tube and differential manometers - Buoyancy - Meta-centric height - determination of stability of floating bodies and submerged bodies.

UNIT 4 EQUATIONS OF MOTION 9 Hrs.

Basic equations of motion: Types of fluid flow-Concept of Control Volume- Control Volume Analysis of mass, momentum and energy. Differential equation of continuity and momentum - Euler’s and Bernoulli’s Equation and its applications. Flow Measurement: Orifice meter, Venturi meter, Piezometer.

UNIT 5 FLUID DYNAMICS AND FLOW THROUGH PIPES 9 Hrs.

Flow through orifices: Classification - Hydraulic co-efficient - Flow through rectangular orifice, Notches and weirs. Laminar and Turbulent flow: Reynolds experiment - Major and minor losses in pipes - Darcy Weisbach’s equation, Chezy’s formula - pipes in series and pipes in parallel - total energy line - hydraulic gradient line - Equivalent pipe.

Max. 45 Hrs.

COURSE OUTCOMES

On completion of the course, student will be able to

CO1 - Analyze the state of stress and strain at any point in a member.

CO2 - Identify, formulate, and solve structural engineering problems.

CO3 - Calibrate flow discharge measuring device used in pipes channels and tanks.

CO4 - Apply Hagen Poisueille’s equation to solve numerical Problems.

CO5 - Characterize laminar and turbulent flows.

CO6 - Interpret different pipe fittings and evaluate the fluid velocity considering major and minor losses.

TEXT / REFERENCE BOOKS

1. Rajput.R.K. “Strength of Materials” 4th Edition, S.Chand & Co., New Delhi, 2002.

2. Khurmi, R.S, “Strength of Materials“, 23rd Edition, S.Chand & Co., 2008.

3. Bansal.R.K., “Fluid Mechanics & Hydraulics Machines”, 9th Edition, Laxmi Publications, 2005.

4. Kumar K. L., “Engineering Fluid Mechanics”, 8th Edition, Eurasia Publication, 2009.

- Teacher: Dr. ANISH M

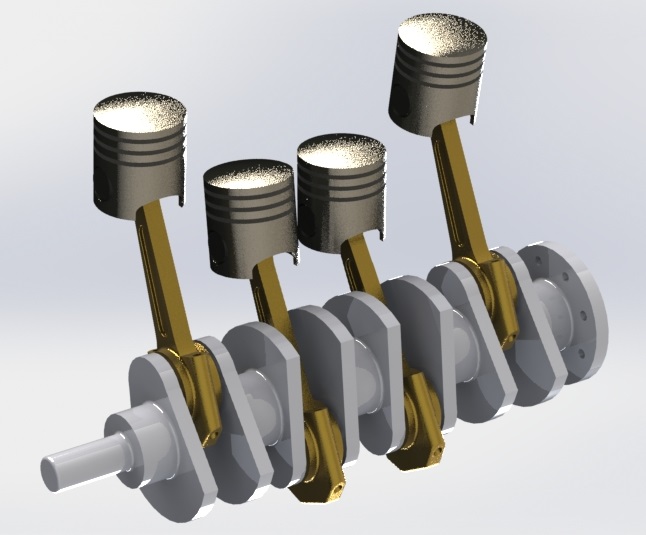

This course enable the students

- To understand the basic concepts of thermodynamics

- To understand the air standard cycles and working principles of four stroke and two stroke engines

- To familiarize with the types of air compressors and their working principle

- To understand the working principles of refrigeration and air conditioning systems

- Teacher: Kanimozhi B

- Teacher: SENTHILKUMAR G

At the end of the course Students will be able to form and solve the nth degree algebraic equations. Using the concept relation between roots and coefficients of equations the student will be able to find the roots of the equation. Reciprocal equations can be solved using the newton’s method. The student will be able to find rank and inverse of a matrix by elementary transformation. Students get a clear idea on finding the characteristic equation and roots of the characteristic equation of a given matrices. Cayley Hamilton theorem gives him a clear idea to find the inverse and higher powers of the given matrix. Student can solve the system of equations using matrix methods

- Teacher: KAVITHA C

- Teacher: MARY METILDA M I

- Teacher: Subhashini N

The ability to identify,reflect upon,evaluate and apply different types of information and knowledge to form independent judgements. Analytical,logical thinking and conclusions base<l on quantitative information willbe the mainobjective of learning this subject.

- Teacher: MOHAMED ISMAIL A

- Teacher: MAHESWARI S

To learn about division algorithm. To have knowledge about fundamental theorem of arithmetic. To be

familiar with linear congruences. To have knowledge in Mobius inversion formula and Euler’s theorem

- Teacher: FRANKLIN THAMIL SELVI M S

Understand the basic rules of logic, including the role of axioms or assumptions and appreciate the

role of mathematical proof in formal deductive reasoning and able to distinguish a coherent argument from a fallacious one, both

in mathematical reasoning and in everyday life.

- Teacher: FRANKLIN THAMIL SELVI M S